Die Cart Advantages Over Fork Trucks

Size

Die Carts have Approx. 30% Shorter Turning Raduis’ Than Fork Trucks

Cost

Die Carts Cost Approx. 25% Less Than A Fork Truck

One Person Die Exchange, No Spotter Needed

Docking

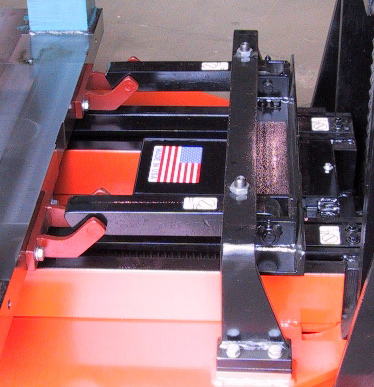

Die Cart Can Dock in Seconds Via Power Latch System, CCTV Camera System, & Docking Mechanisms

Eliminates Current Damage to Press and Building Columns

Safety

Die Cart is Attached to Press/Rack During Push/Pull of Die

Die is Under Control/Secured in a Locked Position During Transport

One Person Die Exchange

Die Rolls on to Rack/Press Surface - No Dropping Die During Push/Pull Sequence (Utilizing Existing Press Rollers)

Transistorized Programmable Variable Speed Control for Driving, Push/Pull, & Lift

Approx. 50% of Our Die Cart Sales are Due to Fork Truck Injury or Die/Press Damage

Why Chose LTS?

Experience

LTS Will Ensure That the System is Fully Operational Prior to Leaving your Plant

Rico Equipment Has Been Building Quality, Heavy-Duty Die Handling Equipment for Over 77 Years, That will last 15-20 Years, 95% Up-Time

LTS Has Installed Turnkey Quick Die Change Systems for More Than 44 Repeat Customers

38 Years Experience Installing Quick Die Change Handling Systems for Over 74 Clients

Training

We Provide In-House Training and On The Floor Die Cart Training

Only Persons Trained by LTS Personnel Will Receive a Certificate of Successfully Completing the Course

Only Those Persons Who Own a Certificate Should Operate the Die Cart

Future Training

Profit/LTS Can Quote and Provide Training Videos for Plant Use in Training Future Operators

Support

LTS Representative is a Phone Call Away

95% of Parts for Die Cart are Stored In-House at Rico

We Will Work with Existing Fork Truck Dealer That is Currently Servicing Your Plant

We Will Attend Run-Off of Die Cart at Rico with Customer to Ensure Die Cart Meets Specifications Per Quote to Approve for Shipment